Why Spashta ?

A need for better supply chain decision making solutions. Our expertise spans all aspects of supply chains and our portfolio includes projects for some of the world’s largest organisations.

Optimizing network performance

A comprehensive range of supply chain services

The Problem

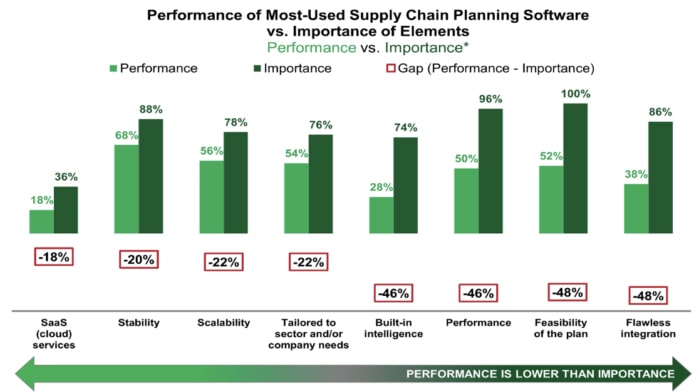

Traditional solutions for supply chain decision making are siloed in approach, inflexible, and with long implementations resulting in low adoption and ROI Users create their own 'Excel clusters' for day-to-day decision making despite having expensive implementations

Root Cause

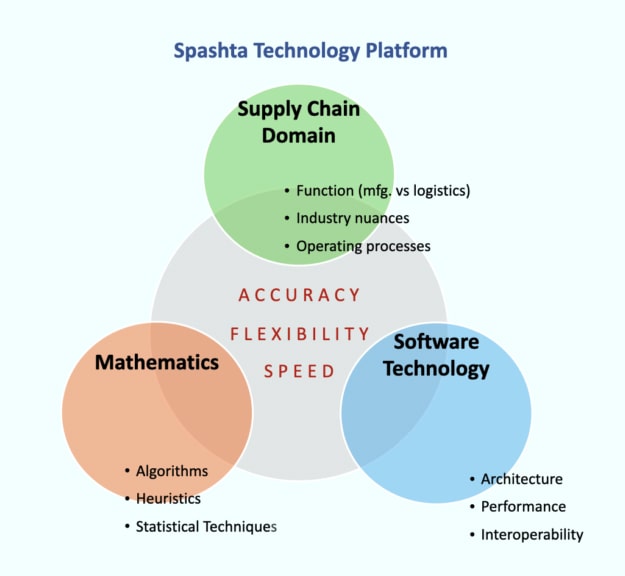

Optimal SCM solution architecture requires Three Critical Dimensions: Supply Chain Domain, Mathematics & Software Technology Traditional solution providers have evolved organically and are good in one or two of these dimensions

Spashta's Goal: Enable supply chain agility with an interactive, intelligent, decision-making platform

Address global, full scale supply chain problems

+

Respond rapidly to business challenges

+

Enable dynamic & boundary less planning

• 5-15% improvement in cost, service level & inventory

• Manage risk & business cycles build supply chain agility

Spashta's edge in Solution Technology

Specific Solution Approaches

Supply Chain Network Design

Inventory Optimization

MILP Optimization

Stochastic Algorithms

Demand Planning

Production Planning & Scheduling

Statistical Algorithms

MILP Optimization & Heuristics

Distribution Planning

Container Load Optimization

Linear Optimization & Heuristics

Combinatorial Optimization

Dispatch Planning

Master Planning / Supply Planning

Combinatorial Optimization & Heuristics

Linear Optimization & Heuristics

E.g. Dimensions of a Master Planning Problem

- Size & Scale ... no of demand points, SKUs, mfg plants, DCs, etc.

- Time Horizon ... no of time buckets being planned into the future

- Complexity ... tiers of supply chain, capacity constraints, shared resources

- Business Rules ... shelf life, lot sizes, attribute based planning, etc.

- Real time ... open orders, stock levels, in-transits, etc.

Spashta's Solver Performance

Efficacy … consider all dimensions of the problem: self learning solvers

Speed … solve large & complex problems in minutes

Agility … perform rapid “what-if scenarios”, fine tune business rules, perform “anchored planning”

Sample Solver Run Statistics

| # of Supply Chain Tiers | 4 |

| # of Mfg Plants | 48 |

| # of Stages of Capacity | 5 |

| # of DCs | 93 |

| # of Resource-Lines | 130 |

| # of SKU-Locations | 124,333 |

| # of Time Buckets | 60 |

| # of Demands | 5,856,000 |

| Shelf Life, Lot Size, Multi-modal Lead Times | |

| Machine | T2.2XL on AWS |

| Run Time | 6 min 29 sec |

Specific Solution Approaches

Supply Chain Network Design

Inventory Optimization

MILP Optimization

Stochastic Algorithms

Demand Planning

Production Planning & Scheduling

Statistical Algorithms

MILP Optimization & Heuristics

Distribution Planning

Container Load Optimization

Linear Optimization & Heuristics

Combinatorial Optimization

Dispatch Planning

Master Planning / Supply Planning

Combinatorial Optimization & Heuristics

Linear Optimization & Heuristics

E.g. Dimensions of a Master Planning Problem

- Size & Scale ... no of demand points, SKUs, mfg plants, DCs, etc.

- Time Horizon ... no of time buckets being planned into the future

- Complexity ... tiers of supply chain, capacity constraints, shared resources

- Business Rules ... shelf life, lot sizes, attribute based planning, etc.

- Real time ... open orders, stock levels, in-transits, etc.

Spashta's Solver Performance

Efficacy … consider all dimensions of the problem: self learning solvers

Speed … solve large & complex problems in minutes

Agility … perform rapid “what-if scenarios”, fine tune business rules, perform “anchored planning”

Sample Solver Run Statistics

| # of Supply Chain Tiers | 4 |

| # of Mfg Plants | 48 |

| # of Stages of Capacity | 5 |

| # of DCs | 93 |

| # of Resource-Lines | 130 |

| # of SKU-Locations | 124,333 |

| # of Time Buckets | 60 |

| # of Demands | 5,856,000 |

| Shelf Life, Lot Size, Multi-modal Lead Times | |

| Machine | T2.2XL on AWS |

| Run Time | 6 min 29 sec |